CONSULTATION » PARQUET » WOOD SPECIES

What is the best type of wood for parquet?

DRAFT * DRAFT * DRAFT: At this point we are revising our parquet advice. In a few weeks you will find out everything about indoor wooden floors here.

type of wood 1

- Advantages: high-quality solid wood, maximum durability

- Disadvantages: time-consuming installation, high acquisition costs

A wooden floor made of solid wood parquet is made entirely of one solid type of wood. This distinguishes it from ready-made parquet, veneered flooring and laminate, where at most the top wear layer consists of real wood.

But the solid wood has its price and is one of the more expensive floor variants compared to ready-made parquet or lamanit. In the long term, however, a floor made of solid wood planks can still pay off. A cheap wooden floor with a low wear layer can be worn out after 10 years and must be removed. Even high-quality engineered wood parquet is difficult to sand down and touch up - and still sometimes costs more than a solid wood floor.

In addition, the treatment of the surface should be considered. Untreated floorboards require a lot of oil or varnish to ensure adequate sealing. Solid wood floorboards that have already been sealed have the advantage that the factory seal is usually more durable and of higher quality than your own seal.

Solid wood floorboards are more complex to lay than ready-made parquet or laminate. They can be screwed, glued or laid floating. In any case, the installation should be carried out by a professional.

type of wood 2

- Advantages: Real wood wear layer

- Disadvantages: only partially sandable

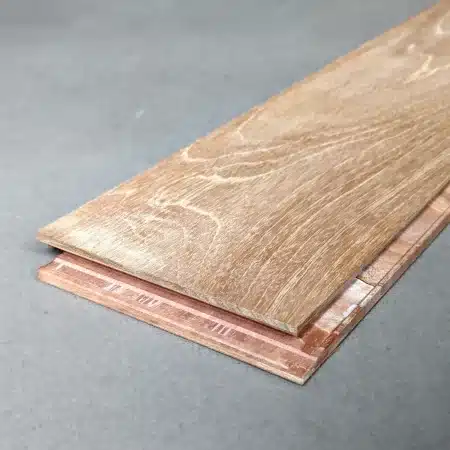

Ready-made parquet and laminate are very similar in structure: It usually consists of three layers, with the lower backing veneer and the middle layer being made of cheap coniferous wood. Only the surface is made of high-quality precious wood and differs here from laminate, where plastic forms the surface.

Sanding down this 2mm to 4mm wear layer on finished parquet is only recommended after consultation with the manufacturer. Some finished parquet floors are not suitable for this type of repair. Others can be sanded down at least once.

Parquet prices can vary greatly. The thickness of the wear layer and the type of wood in the wear layer are decisive. The thicker and higher the quality of the wood in the wear layer, the higher the price. In some cases, prices per square meter can be achieved here, as with solid wood floorboards.

However, laying engineered parquet is much easier than laying solid wood floorboards. Click parquet can also be laid by hobby do-it-yourselfers, for example.

type of wood 3

- Advantages: Very cheap, easy installation

- Disadvantages: short lifespan, no visible real wood

Laminate, like the finished parquet, usually consists of three layers, with a thin plastic layer forming the top layer in the laminate. This is usually based on a wood surface, but can represent any other pattern and color depending on the print.

Laminate floors cannot be sanded down. Therefore, this floor usually has a significantly shorter lifespan than real wood floors.

Despite this, laminate has two undeniable advantages: its price is very low and it is very easy to lay. You can get a laminate floor for a good 10 euros per square meter. The reason for the low price lies in the structure of the laminate: wood-based panel, photo paper and resin seal. Real wood, which makes solid wood floorboards and engineered parquet expensive, is hardly available - apart from the glued HDF layer that forms the core board.

Laminate is usually laid floating and is very easy to do.