CONSULTATION » Decking boards » saw blade

How do I find the right saw blade?

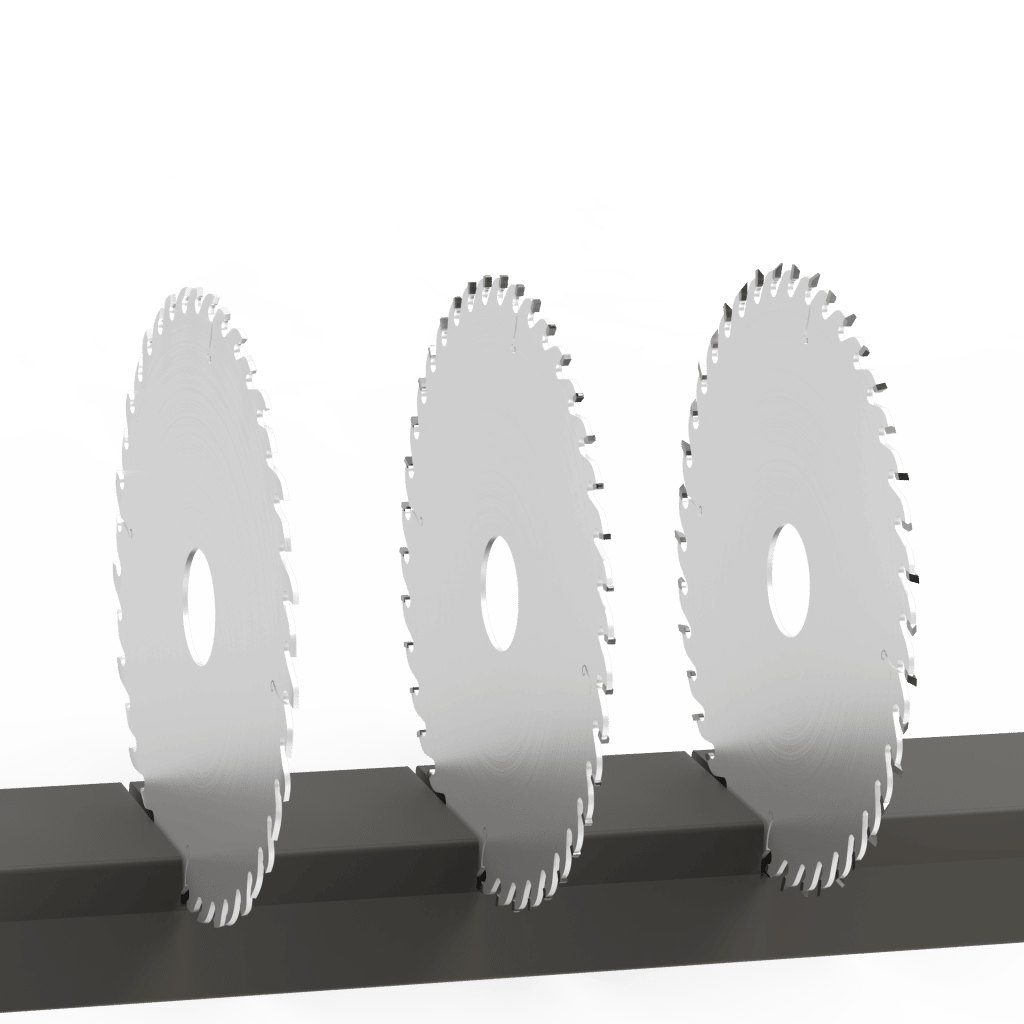

Hardwoods place special demands on the tools used. Especially when sawing, the right choice of saw blade can be crucial and make laying much easier.

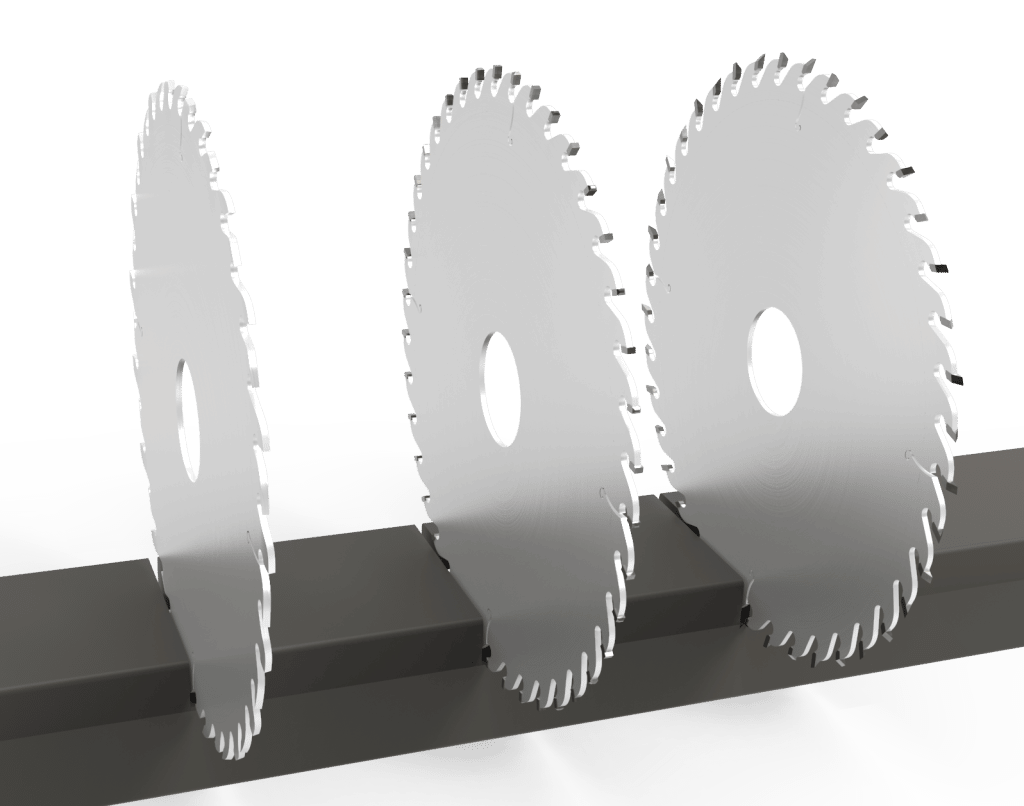

Format Material number of teeth tooth shapeWhich format should my saw blade have?

As a rule, the format of circular saw blades is specified as follows: Ø diameter x Ø bore (mount for the saw) and number of teeth, E.g.: Ø 210 mm x 30 mm x 60 teeth.

In the case of hand-held circular saws and plunge-cut circular saws, the size of the saw blade is determined by the housing of the respective model. The hole for the saw blade is also specified. By using a reducing ring, there is at least some flexibility in the bore (saw blade holder), otherwise please first check which format your saw prescribes for the saw blade.

Especially at Cordless circular saws offer themselves thinner saw blades on. Due to the thinner construction, less energy is consumed with just as good cutting results. This is also referred to as thin section. These saw blades can also be used with "normal" circular saws.

What material should my saw blade be made of?

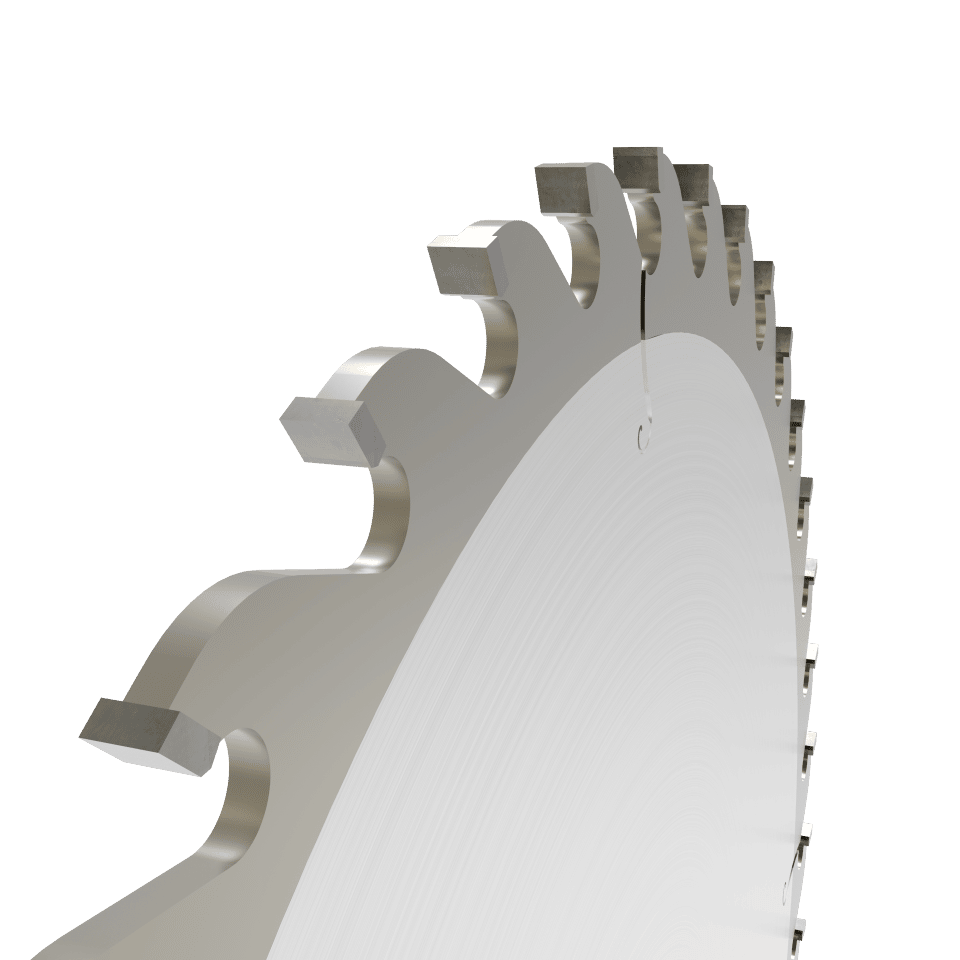

Recommended for cutting hardwoods Carbide (HM)-Saw blades. In contrast to chrome vanadium (CV) saw blades, the teeth on these are attached/soldered onto the "master blade" and consist of a hard metal or a diamond material. These are much more resistant to heat and have a significantly lower regrinding requirement than pure CV or even HSS steel and can usually also cope with nails in the wood.

HM saw blades are often also called HW (carbide material) led and also have this due to the combination of the two materials (the more expensive material is only used for the teeth). best value for money.

What number of teeth is right for the saw blade?

The number of teeth on the saw blade determines the cutting quality on the one hand and the feed force when sawing on the other, ie how much wood is “removed” with one tooth. The decisive factor here is that the number of teeth must always be seen in relation to the size of the saw blade.

Do I need a low or high tooth count?

At a low number of teeth Less (feed) force is required because the teeth are larger and remove larger chips. In addition, larger teeth are less prone to clogging. However, these are also coarser in comparison and ensure a poorer cross-section. A lower number of numbers works well for rip cuts along the grain of the wood, for example. However, the sectional image is rather rough.

An higher number of teeth Conversely, this leads to a cleaner cut, although more (feed) power is required because less wood is removed with the teeth. Especially with rip cuts, there is a risk that the saw will become blocked. However, finer teeth are very well suited for cross-sections.

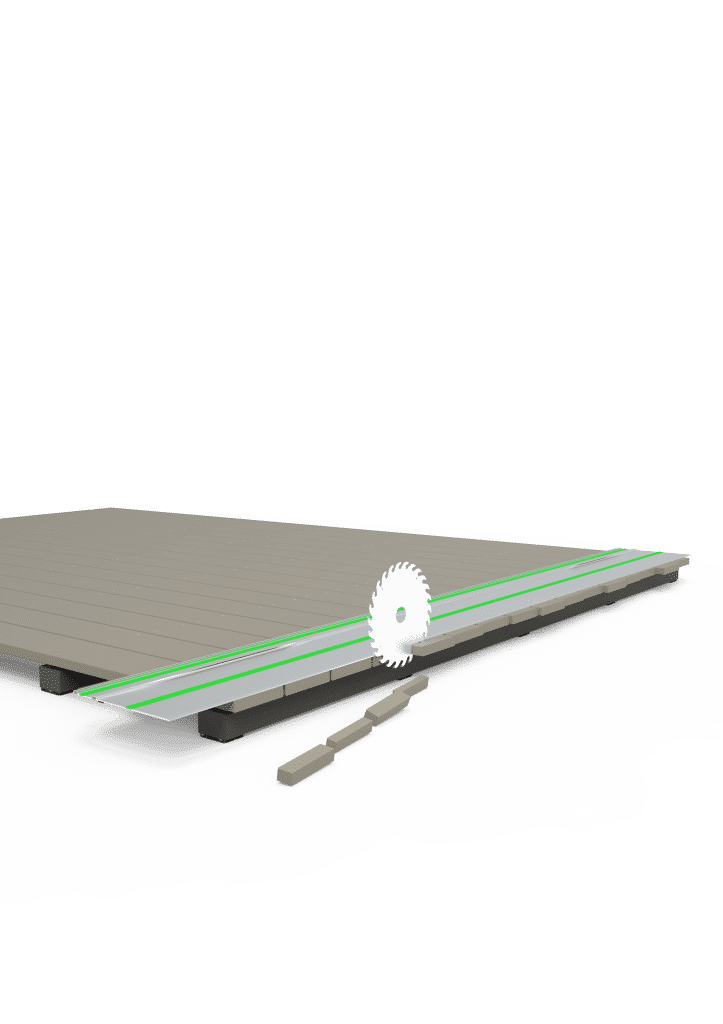

The correct number of hardwoods in terrace construction

For tropical hardwoods like those we stock, the saw blade should have a medium to high number of teeth. This gives you a relatively clean cross-section of the planks when you cut them at the end. On the other hand, you still have enough feed force to split a plank lengthways. This can happen if your patio area cannot be covered with whole planks alone or you have to narrow the planks for the facing.

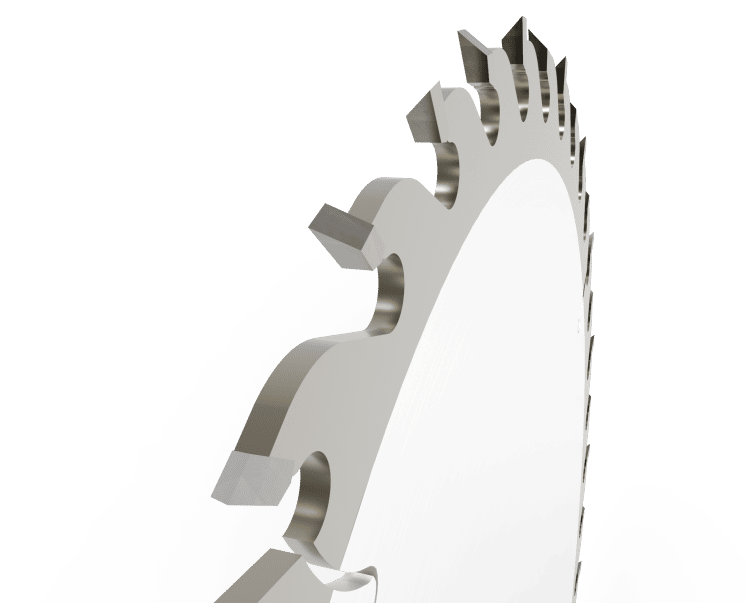

What does free cut mean for saw blades?

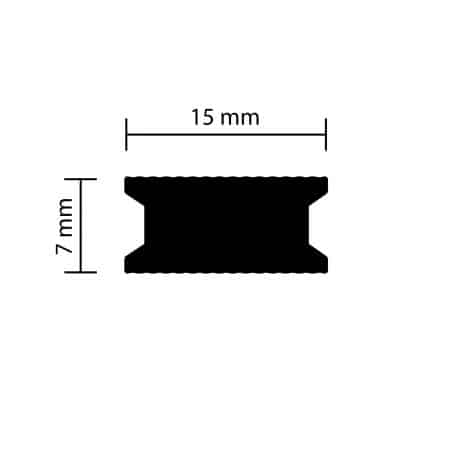

Under free cut refers to the property of saw blades that the teeth are wider than the main blade. This is achieved either by actually putting on wider teeth (HM saw blades) or by setting the teeth (CV saw blades).

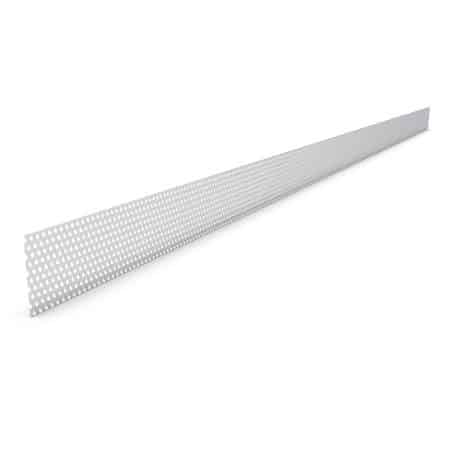

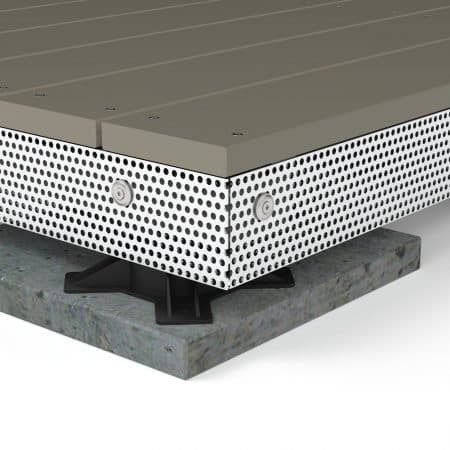

This causes less friction and heat when sawing, since only the teeth are in contact with the wood when cutting. This also prevents the blade from jamming in the saw cut when sawing (see picture). The advantage of wider "set" teeth compared to set teeth is the longer service life (less grinding required). Therefore, especially with hardwood, wider teeth should be preferred to the set version.

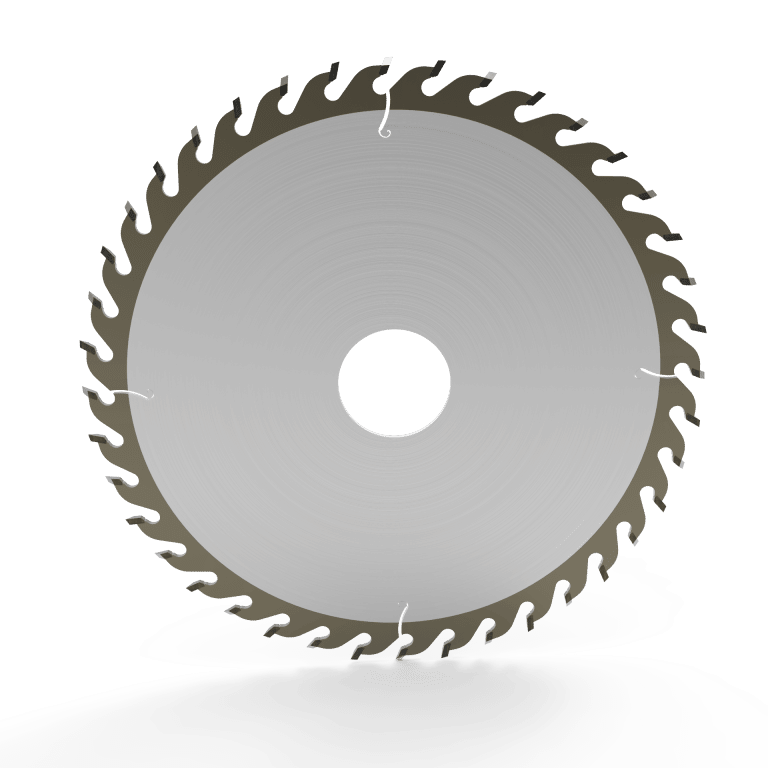

Which tooth shape is the right one for hardwood?

There are different types of tooth shapes and their arrangement on the blade. The most common tooth shapes on HM saw blades include, for example, alternating teeth, trapezoidal teeth or trapezoidal flat teeth. The correct tooth shape depends on the application.

For cutting tropical hardwoods in terrace construction, we recommend the alternate tooth as the tooth shape of the HM saw blade. Due to the mutual grinding of the teeth, each individual tooth is less heavily loaded. This results in a longer service life (less frequent regrinding) and smoother running when sawing. In addition, the pronounced tips of the teeth lead to a high quality of cut, both in cross and longitudinal cuts.

Plan a wooden terrace now for free.

We will provide you with a laying plan and an offer with all the accessories and transport costs. We can also plan extras such as construction height or patio steps for you.

terrace plannerTable of Contents

process

calculate demand

calculate costs

Order wood samples

Wood decking shipping

interim storage

Building instructions wooden terrace

grocery list

Prepare the subsurface

meadow or earth

stone or concrete

roof or balcony

hillside

Lay out the foundation

Establish height compensation

Lay the substructure

Install decking

Select saw blade

Screw the decking boards together

Building instructions terrace screws

Assembly instruction clips

Fade wooden terrace

build stairs

Decking boards crooked

Typical mistakes

Care for

Clean

Enjoy

Decking quality

Best decking wood

Wood species comparison

hand sorting

cracks and curvature

Durability wooden deck

Wood vs Aluminum

Concealed screw connection comparison

branded products

finger joint