CONSULTATION » Decking boards » Wood or aluminium

Substructure: wood or aluminium?

What is more suitable for terrace construction? The answer is usually: wood – because with aluminum the risk of screws breaking off is very high. Depending on the project and priorities, however, some of the disadvantages of aluminum can be compensated for with the right accessories.

Comparison of wood vs. aluminum

In the following overview we compare the advantages and disadvantages of wood and aluminum as a substructure. Below you can read a detailed evaluation of the properties in relation to terrace construction.

from BioMaderas

Span:

up to 200cm

Lifespan:

at least 25 years

delay:

Max. 1%

environmental balance:

very well

from BioMaderas

Span:

110cm

Lifespan:

practically indestructible

delay:

Max. 0,1%

environmental balance:

bad

Aluminum substructure

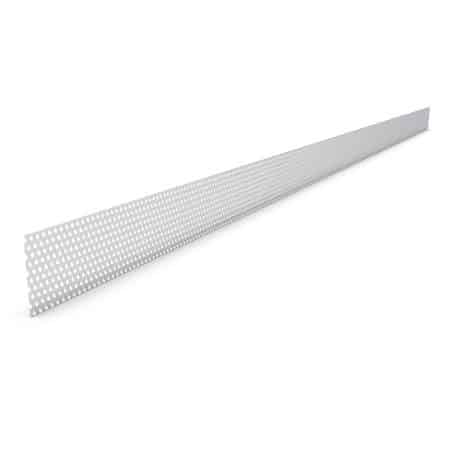

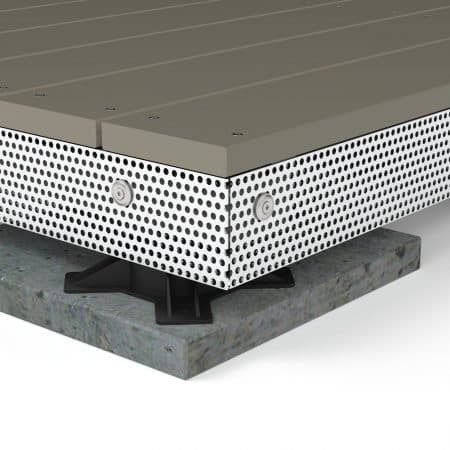

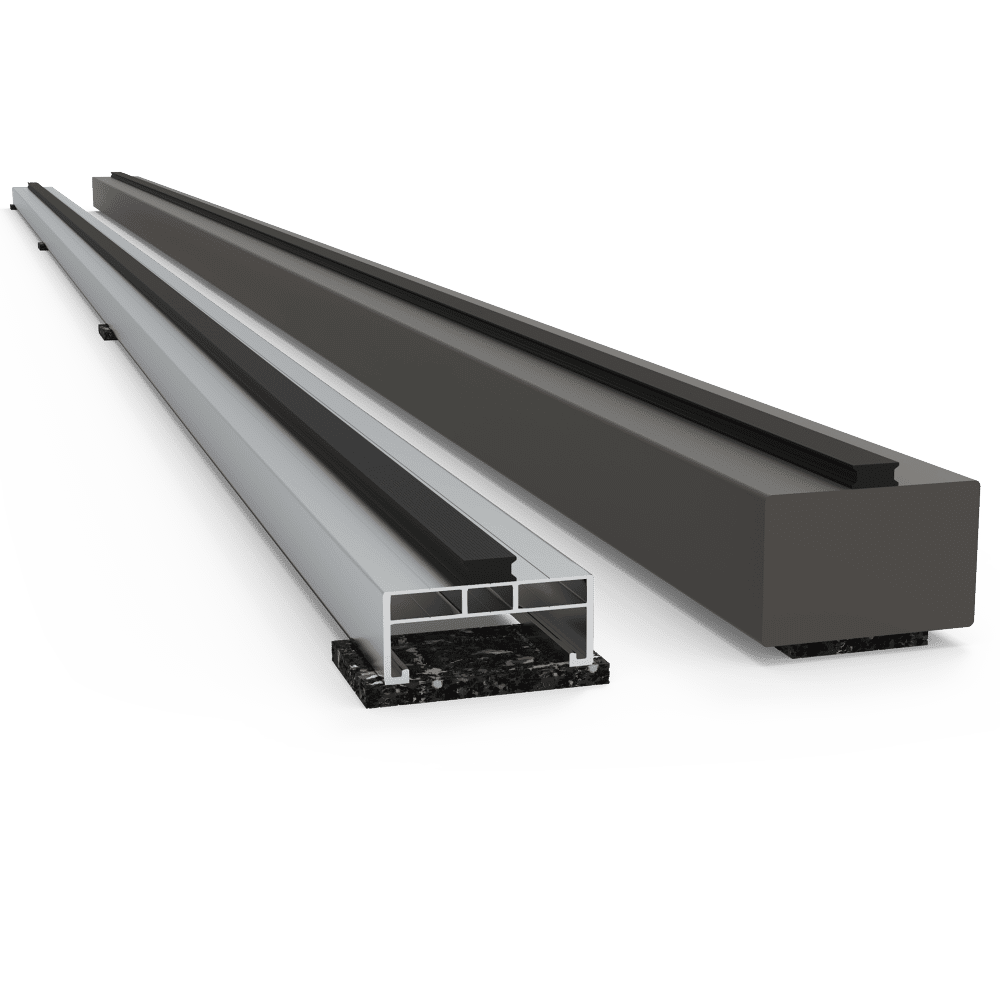

Prerequisite A good aluminum substructure requires a wall thickness of at least 2mm and a construction with a double bridge so that the screw sits in two layers of aluminium. Our aluminum substructure meets both requirements.

Benefits an aluminum substructure: It is very straight and practically indestructible. Dimensional accuracy can simplify the construction of a terrace. The fact that the substructure lasts longer than the covering is only an apparent advantage. Because aluminum often cannot be used for the second terrace because there are already drill holes.

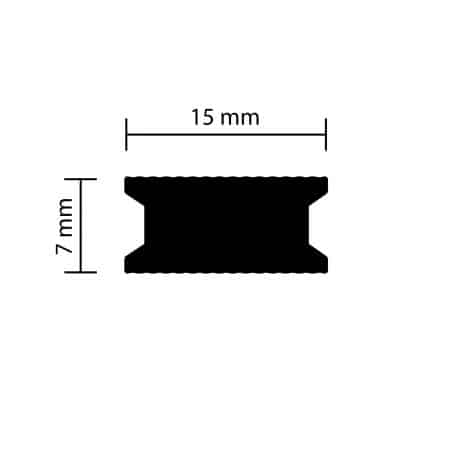

Disadvantage the aluminum substructure: the material is unyielding. When working the wooden decking stresses can therefore occur which cannot be absorbed by the aluminium. In the end, this can lead to the screw tearing. In the case of a visible screw connection, however, a distance profile be installed to prevent tearing of the through a shearing area patio screw to prevent the BioMaderas Clips are structured in such a way that the risk is already significantly reduced here. Nevertheless, we recommend a construction with a wooden substructure.

wooden substructure

Prerequisite for a good wooden substructure: The type of wood used in the substructure should be at least as durable as the top covering. A manual sorting should take place in advance so that unobstructable woods with excessive warpage are sorted out. Both requirements are met by our wooden substructures.

Advantage the wood substructure: A wood-wood construction goes better together. There is no metallic squeaking or creaking, there is no build-up of tension and the screw heads are prevented from being torn off. In addition, a wooden substructure made of a dense material achieves a large span and saves support points and pedestals.

Disadvantage the wooden substructure: wood is never as straight as aluminium. However, a slight distortion can usually be compensated for by screwing the construction wood to the floorboards.

Table of Contents

process

calculate demand

calculate costs

Order wood samples

Wood decking shipping

interim storage

Building instructions wooden terrace

grocery list

Prepare the subsurface

meadow or earth

stone or concrete

roof or balcony

hillside

Lay out the foundation

Establish height compensation

Lay the substructure

Install decking

Select saw blade

Screw the decking boards together

Building instructions terrace screws

Assembly instruction clips

Fade wooden terrace

build stairs

Decking boards crooked

Typical mistakes

Care for

Clean

Enjoy

Decking quality

Best decking wood

Wood species comparison

hand sorting

cracks and curvature

Durability wooden deck

Wood vs Aluminum

Concealed screw connection comparison

branded products

finger joint