Betterwood " Advisory » wooden panels » Finger jointing

What does "finger-jointed" mean?

Finger-jointed means that two solid wood parts interlock and are glued by wedge-shaped teeth. This creates an extremely stable and almost distortion-free connection between shorter pieces of wood to a theoretically infinitely long piece of wood.

The Brand

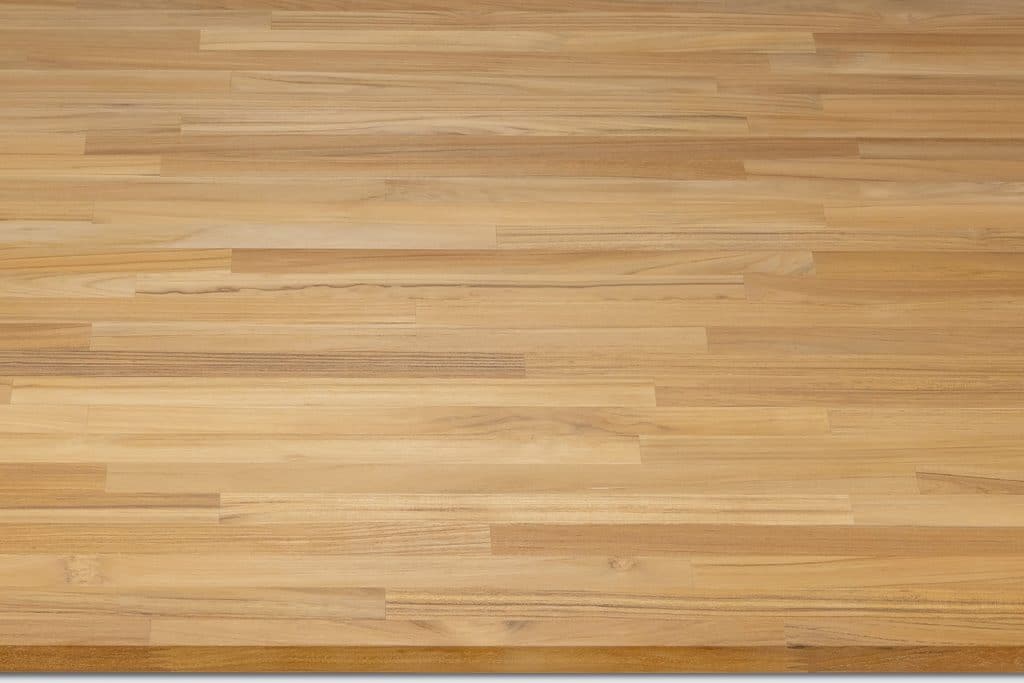

This method is used, for example, with laminated wood panels. They are available with continuous slats and finger-jointed slats. With continuous slats, the individual wooden sticks are glued together lengthwise and go through to the end of the board. In the case of finger-jointed laminated wood panels, the individual slats are finger-jointed together lengthwise. What are the differences?

stability and length

From a technical point of view, there are no serious advantages or disadvantages between continuous and finger-jointed laminated wood panels. However, finger-jointed panels can be a lot more stable. With some types of tropical wood, finger-jointing is advantageous for another reason: using shorter pieces of wood, which are then finger-jointed, reduces the risk of warping considerably.

Tropical types of wood are significantly denser than domestic types of wood - this is the reason for their enormous durability. However, they also tend to warp when there are temperature fluctuations. Therefore, the care and processing instructions must be observed in order to minimize the risk.

Continuous laminated wood panels are usually no longer than two meters and in most cases rather shorter - at least as far as teak panels are concerned. Finger-jointing makes it possible to produce longer panels, which can be up to three meters long.

Appearance

In the production of glued wood panels, care is taken to ensure that the wooden sticks used are similar in color and match each other. This is particularly important for finger-jointed glued panels, in order to get a surface that is as smooth as possible, despite the color changes that are typical of wood.

environment and prices

Finger-jointed glued panels are a more sustainable and resource-saving product. During production, shorter pieces of wood can also be used and thus as much of the tree as possible is processed.

This is not possible with continuous slats. This also explains the price differences between continuous and finger-jointed wood panels: the waste - the then useless "waste" - in the production of continuous glued wood panels is many times larger. Therefore, such panels are usually more expensive than finger-jointed comparable products.